The dirty truth about Polished Concrete maintenance

Tom Loe • April 22, 2020

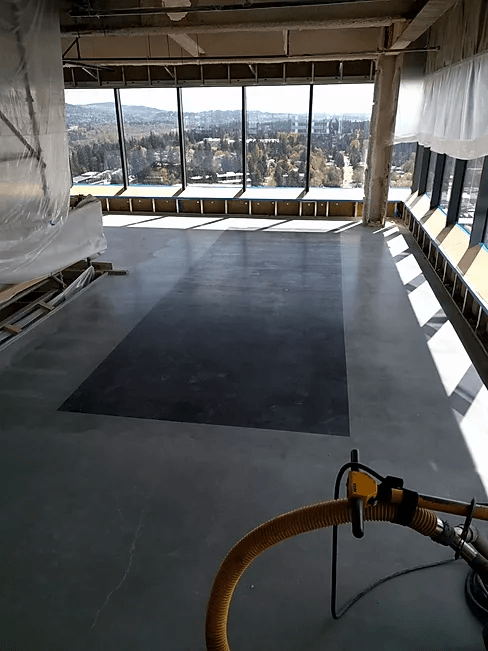

Durability, aesthetics, the high degree of light reflectivity, reduced construction costs, minimal environmental impact and the ease of maintenance are just a few reasons why polished concrete is quickly becoming the preferred choice of many retailers, architects and engineers across the country.

As the popularity of polished concrete continues to rise, so does the demand for a sustainable solution to proper concrete maintenance. Polished concrete has numerous advantages over carpet and VCT flooring including its reduced need for constant maintenance, however it still requires a certain level of care in order to keep it looking as beautiful as the day it was polished.

Over the years, polished concrete has been sold as a “maintenance free” flooring system. Industry experts say that is a common misnomer, however.

“Too often, we run into people who believe that once the concrete floor has been installed, it maintains itself,” says Claudia Lezell, vice chair of the Institute of Inspection Cleaning and Restoration Certification (IICRC). “This couldn’t be further from the truth. Like most other hard floor surfaces, concrete maintenance requires a specialized approach that takes several factors into consideration — otherwise, it can fail.”

“Polished concrete, unlike VCT, is relatively low-maintenance flooring, since it does not require waxes or topical sealers. It does however, like any flooring application, require specific preservation methods in order to keep its glossy appearance,” says Bill Griffin, owner of Cleaning Consultants Inc. in Seattle, WA.

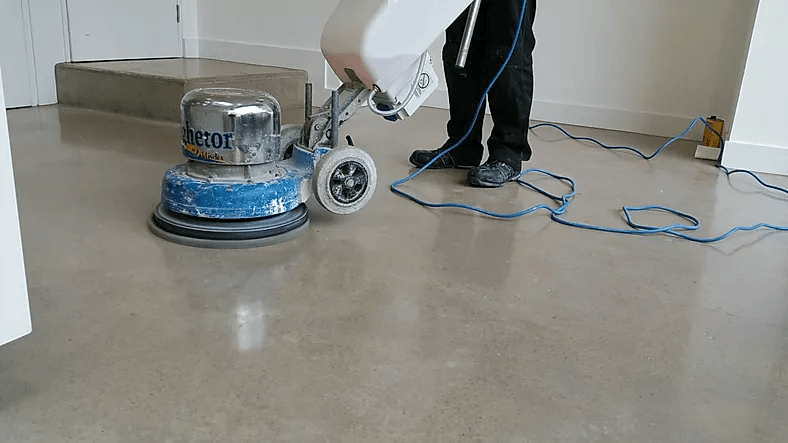

A series of grinding and polishing steps are used to initially create a high-gloss polished concrete floor. A coarse grinding tool, such as a diamond disk, is used to either wet or dry grind the concrete. Then a series of progressively less abrasive diamond pads grind and polish the floor until the desired level of gloss is attained. Facilities can choose the level of sheen — from matte to high-gloss — that meets their maintenance and aesthetic requirements. This process includes several levels of grinding, application of densifiers, and burnishing. A licensed concrete contractor such as Reflex Flooring, with specialized equipment and tools typically performs this initial process.

The various levels of shine for polished concrete range from low gloss to reflective, mirror-like finishes. “Polished concrete, like any floor, still requires regular sweeping and cleansing in order to remove dust and grime accumulation,” says Andy Loe, Manager of Reflex Flooring. “Using a high quality, neutral pH cleanser will add life and years of shine to your polished concrete floor.” Finding a professional grade, pH neutral cleanser is much less abrasive and harmful than acidic or alkaline based cleansers.

One last consideration when cleaning your polished concrete floor is choosing the correct cleansing pad. If a rotary swing-machine or auto-scrubber is used, be sure to use non-abrasive fibers or diamond impregnated pads, which will actually improve the shine of the floor over time. These are made with either synthetic or natural fibers which will not open pores, or damage the floor.

“I advise all of our customers that in order to maintain a high gloss shine, it is essential to follow recommended cleaning guidelines and schedules. This includes the use of pH neutral cleaners and high quality cleansing pads. As you notice reduced shine at any time, switch pads to a diamond impregnated pad until desired shine returns,” says Loe.

Concrete polishing is used more for commercial flooring than residential flooring, but polishing is quickly becoming more popular in residential applications, as more homeowners realize the cost benefit and easy no-wax advantage of concrete polishing. The beautiful shine that concrete polishing creates means that there is rarely a need to wax the polished floor. Some new high-gloss finishes never need to be waxed or have coatings applied in order to keep their shine. The polishing process is similar to sanding. Large machines are used to grind down the the concrete surface to the smoothness and shine desired.

Homeowners, retailers, big-box stores, educational and medical facilities are choosing polished concrete for their floor finish because of the competitive advantage polished flooring offers over other types of floor coverings. Decorative concrete in the form of polished floors has become the logical choice because of the great value it delivers, and because it can compete aesthetically as well. Residential Polished Floor Benefits: Cost savings: Traditional floor covering materials are not necessary when the slab on grade is used as the finished floor surface Longer life-cycle savings: Polished floors are not as vulnerable to damage as other materials and do not need replacing Easy to clean: Won't harbor dust, dirt, allergens Available in wide variety of colors and designs